3D Printer Buyer’s Guide

1 Introduction

3D Printing Has Come Of Age

3D Printing is more than just prototyping. Today, 3D Printing off ers transformative advantages at every phase of creation, from initial concept design to production of fi nal products and all steps in between. Today’s competitive environment makes choosing the right 3D printers for every phase of creation more important than ever.

Just a few years ago in-house 3D printing was enjoyed by only a few professional design engineers and was often limited to printing concept models and some prototypes. Once considered a novel luxury, 3D printing has proven to yield long-term strategic value by enhancing design-tomanufacturing capabilities and speeding time to market. Today, 3D printing technologies have allowed an ever growing number of creators to unleash and multiply the benefi ts of rapid in-house 3D printing across the entire creation process.

Leading companies are now using 3D printing to evaluate more concepts in less time to improve decisions early in product development. As the design process moves forward, technical decisions are iteratively tested at every step to guide decisions, both big and small, to achieve improved performance, lower manufacturing costs, delivering higher quality and more successful product introductions. In pre-production, 3D printing is enabling faster fi rst article production to support marketing and sales functions, and early adopter customers. And in fi nal production processes, 3D printing is enabling higher productivity, economical customization, improved quality and greater effi ciency in a growing number of industries.

2 What is the right 3D printer technology for your application?

Choosing the right 3D printer among the various alternatives may at fi rst seem like a daunting task. There are signifi cant diff erences in how each printing technology turns digital data into a solid object. Today’s 3D printers can use a variety of materials with vast diff erences in structural properties, feature defi nition, surface fi nish, environmental resistance, visual appearance, accuracy and precision, useful life, thermal properties and more. It is important to fi rst defi ne the primary applications where 3D printing will be used to guide the selection of the right technologies that will provide the greatest positive impact for your business. This article will highlight some of the common 3D printing applications, and outline some key attributes to consider when selecting a 3D printer.

Concept Models

Concept models improve early design decisions

that impact every design and engineering activity

that follows. Selecting the right design path

reduces costly changes later in the development

process and shortens the entire development

cycle so you get to market sooner. Whether

designing a new power tool, offi ce accessory,

architectural design, footwear or toy, 3D printing

is the ideal way to evaluate alternative design

concepts and enable cross-functional input from

all stakeholders to make better choices.

During this early phase of creation, it is desirable

to quickly, and aff ordably evaluate numerous

design alternatives with models that look like the

real thing, but do not typically need to be fully

functional. Stakeholders can better visualize

the design intent when they can see and touch

alternative concepts side-by-side enabling faster,

more eff ective decision making .

For most concept modeling applications the key

performance attributes to look for in a 3D printer

are print speed, part cost and life-like print output.

Verifi cation Models

As product designs begin to take shape, designers need to verify design elements to ensure the new product will function as intended. In-house 3D printing allows design verifi cation to be an terative process where designers identify and address design challenges throughout the design process to spur new inventions or quickly identify the need for design revisions.

Applications may include form and fi t, functional

performance, and assembly verifi cation to name

a few. Verifi cation models provide real hands-on

feedback to quickly prove design theories through

practical application. For verifi cation applications

the parts should provide a true representation

of design performance. Material characteristics,

model accuracy and feature detail resolution are

key attributes to consider in choosing a 3D printer

for verifi cation applications.

Pre-Production Applications

As product development converges on the fi nal

design, attention rapidly turns to manufacturing

start-up. This stage often involves signifi cant

investment in tooling, jigs and fi xtures necessary to manufacture the new product. At this stage the supply chain expands with purchase commitments for the raw material and other required components. Lead time for these required items can stretch out time to market, and 3D printing can, in a variety of ways, reduce the investment risk and shorten the time cycle for product launch.

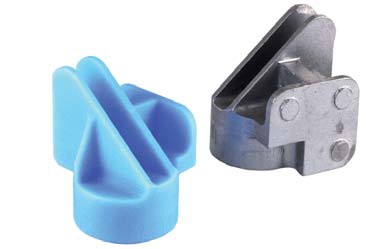

Pre-production 3D printing applications include

rapid short-run tools, jigs and fi xtures to enable

early production and assembly of fi nal products

as well as end use parts to produce fi rst article

functional products for testing and early customer placements.

At this stage the functional performance of the

print materials is critical. Accuracy and precision

are also of paramount importance to ensure fi nal product quality is achieved and manufacturing tooling will not require expensive and timeconsuming rework.

Digital Manufacturing

Some 3D printing technologies can print virtually

unlimited geometry without the restrictions

inherent with traditional manufacturing methods,

thus providing designers greater design freedom

to achieve new levels of product functionality.

Manufacturing costs are reduced by eliminating

time and labor intensive production steps

and reducing raw material waste typical with

traditional subtractive manufacturing techniques.

3D printed components may be end use parts or

sacrifi cial production enablers that streamline the

production fl ow. Leading companies in industries

as diverse as jewelry, dental, medical instruments,

automotive and aerospace have adopted 3D

printing to produce end use parts, or casting

patterns and molds, to reduce manufacturing

costs, enable greater customization, improve

product quality and performance, and reduce

production cycle times.

For manufacturing applications the key 3D printer

attributes are high accuracy and precision, and

specialized print materials specifi cally engineered

for application requirements. For some medical

and dental applications, materials may need to

meet specifi c biocompatibility requirements.

3 3D Printer Performance Attributes

Selection of the right 3D printer is driven by application requirements and matching the key

performance criteria that will provide the best all-around value. Here are some specifi c 3D printer

performance attributes to consider when comparing alternate 3D printers.

3D Printer Buyer’s Guide Page

Part Cost

Part cost is typically expressed in cost per volume such as cost per cubic inch or cost per cubic centimeter. Costs for individual parts can vary widely even on the same 3D printer depending on specifi c part geometry, so be sure to understand if the part cost provided by a vendor is for a specific part, or a “typical” part that is an average across a group of diff erent parts. It is often helpful to calculate part cost based on your own suite of STL files representing your typical parts to determine your expected part costs. In order to properly compare claims made by various vendors it is also important to understand what has, and has not, been included to arrive at the part cost estimate.

Some 3D printer vendors will only include the

cost of a specifi c volume of the print material that equals the measured fi nished part volume. This method does not adequately present the true cost of the printed parts as it excludes the support material used, any process waste generated by the print technology, and other consumables used in the printing process. There are signifi cant

diff erences in the material effi ciency of various 3D printers and understanding the true material consumption is another key factor in accurately comparing print costs.

Part cost is driven by how much total material a 3D printer consumes to print a given set of parts and the price of the materials consumed. The lowest part costs are typically found with powder based 3D printing technologies. Inexpensive gypsum powder is the base model material that forms the bulk of the part. Unused powder is continually recycled in the printer and reused resulting in part costs that may be one-third to one-half the price of parts from other 3D printing technologies.

the spectrum of 3D printing technologies. The best comparisons are visual inspection of parts produced on diff erent technologies. Look for razor sharp edge and corner defi nition, minimum feature size, sidewall quality and surface smoothness. Use of a digital microscope may be helpful when examining parts as these inexpensive devices can magnify and photograph small features for comparison. When 3D printers are used for verifi cation testing it is critical that the printed parts accurately refl ect the design. Depending on the type of verifi cation testing

being done, compromise in feature detail quality can reduce the accuracy of testing results.

Accuracy

3D printing produces parts additively, layer by layer, using materials that are processed from one form to another to create the printed part. This processing may introduce variables such as material shrinkage that must be compensated for during the print process to ensure fi nal part accuracy. Powder-based 3D printers using binders typically have the least shrink distortion

attributable to the print process and are generally highly accurate. Plastic 3D printing technologies typically use heat, UV light or both as energy sources to process the print materials adding additional variables that can impact accuracy. Other factors impacting 3D print accuracy include part size and geometry. Some 3D printers provide varying levels of print preparation tools for fine tuning accuracy for specifi c geometries. Accuracy claims by manufacturers are usually for specific measurement test parts and actual results will vary depending on part geometry, so it is important to defi ne your application accuracy requirements and test the 3D printer under consideration using your specifi c application geometry.

Material Properties

Understanding the intended applications and

the needed material characteristics is important in selecting a 3D printer. Each technology has strengths and weaknesses that need to be factored in when selecting an in-house 3D printer. Claims about number of available materials should be viewed with caution as that does not guarantee the available materials will provide the real functional performance needed. It is vital that

parts from 3D printers being evaluated be tested in the intended application prior to making a purchase decision. Stability of parts over time and across various use environments are not.

Some materials may have rapidly deteriorating functional properties at temperatures slightly above the stated HDT while another material may have slow degradation of properties thus expanding the temperature range in which the plastic is useful. Another example is the eff ect of moisture on the part. Some 3D printed plastics are watertight while others are porous, allowing the part to absorb moisture potentially causing the part to swell and change dimensions. Porous parts are typically not suitable for high-moisture applications or pressurized applications and may require further labor-intensive post processing to be useable under those conditions.

New “crossover” 3D printers by 3D Systems

combine the proven performance of

Stereolithography (SLA®) with the simple

usability of in-house 3D printers. These inhouse 3D printers off er an expanded range of plastic materials that truly off er the functional performance of ABS, polypropylene and polycarbonate plastics in a single 3D printer. They offer easy, fast and aff ordable material changeovers allowing one 3D printer to provide a wide range of addressable plastic applications. When looking at technologies that claim numerous materials, pay particular attention to material waste that is generated during material changeover. Some of these 3D printers have multiple print heads that must be fully purged, thus wasting expensive print materials in the process.

Color

There are three basic categories of color 3D

printers; color-choice printers that print one color at a time, basic-color printers that can print a few colors together in one part, and full-spectrum color printers that can print thousands of colors in a single part. The only 3D printers available today that print the full spectrum of colors are the ZPrinters®, by 3D Systems. They can achieve the same type of color on 3D printed models that color document printers display on paper with up to 390,000 unique colors and a virtually infinite number of color combinations resulting in

incredibly life-like models. In addition to putting life-like colors in all the right places, ZPrinters can apply photos, graphics, logos, textures, text labels, FEA results and more, and can produce models that are diffi cult to distinguish from the real product.

4 Conclusion

3D printing can off er benefi ts across the entire creation process from initial concept design to

fi nal manufacturing and all steps in between. Diff erent applications have unique needs and

understanding those application requirements is critical when choosing a 3D printer. Multiple

systems may off er broader use opportunities than a single system, so identifying your unique

requirements to apply 3D printing across your entire design-to-manufacture process can shorten

time-to-market, improve product performance, streamline and cost-reduce manufacturing, and

improve product quality and customer satisfaction will help you defi ne the ideal 3D printing

capability for your organization.

Learn more about 3D Systems at www.3dsystems.com.

Print Speed

Depending on the vendor and the specific

technology, print speed may mean diff erent

things. Print speed may be defi ned as time

required for printing a fi nite distance in the

Z-direction (e.g. inches or mm per hour in the

Z-direction) on a single print job. This method

is usually preferred for 3D printers that have

stable vertical build speeds independent from

the geometry of the parts being printed and/

or independent from the number of parts being

printed in a single print job. 3D Printers with

higher vertical build speeds and little or no speed loss due to part geometry or number of parts in the print job are ideal for concept modeling because they enable the rapid production of numerous alternative parts in the shortest time period.

Another method to describe print speed is

time required to print a specifi c part or to print

a specifi c part volume. This method is often

used for technologies that quickly print a single

simple-geometry part, but slow down when

additional parts are added to a print job or when the complexity and/or size of the geometries being printed increase. The resulting degraded build speed can slow down the decision making process and defeat the purpose of having anin-house 3D printer for concept modeling. While higher print speed is always considered benefi cial, it is especially critical for concept modeling applications. 3D printers that have high vertical build speed independent from part quantity and complexity are typically preferred for concept modeling applications because they can print a larger number of alternative models quickly for side-by-side comparisons to accelerate and improve the early decision making process.

Some plastic part technologies use one

consumable material for printing both the part

and the supports needed during the printing

process. These technologies typically produce

sparse support structures that are easily removed using less material to produce the supports than other plastic part technologies. Most single material 3D printers do not generate signifi cant in-process waste making them extremely material effi cient and cost eff ective.

Other plastic technologies may use a separate, less expensive support material that is removed after printing by either melting, dissolving or blasting with pressurize water. These technologies typically use greater amounts of material to print the supports. Dissolvable supports may require the use of strong, caustic chemicals that mandate special handling and disposal precautions. Waterblasting methods require a water source and drain that can add thousands to your site preparation cost. This method is labor intensive and can result in damage to fi ne part features as force is applied to remove supports. Also, supports located in hard to access cavities may be stranded and impossible to blast away. The fastest and most effi cient support removal is available with 3D printers using melt-away wax support material. Melt-away supports can be quickly removed in batches using a specialized fi nishing oven with minimal labor and no surface force that can damage fragile fi ne features. Also, supports can be removed from otherwise inaccessible internal cavities providing the widest fl exibility to successfully print complex geometries. Removal of the wax supports does not require the use of chemicals and the support wax can be disposed with ordinary trash eliminating the need for special handling.

Be aware that some popular 3D printers blend

expensive build material into the support material during the printing process to create the supports thereby increasing the total cost of materials consumed during the print. These printers also typically generate greater amounts of in-process material waste thereby using more total material by volume to print the same set of parts.

Feature Detail Resolution

One of the most confusing metrics provided on

3D printers is resolution and should be used with caution. Resolution may be stated in dots per inch (DPI), Z-layer thickness, pixel size, beam spot size, and bead diameter just to name a few. While these measurements may be helpful in comparing resolution within a single 3D printer type, they are typically not good comparison metrics across discernible from standard published specifi cations and may lead to limitations in actual usefulness if not fully considered and tested.

For concept modeling applications, the actual

physical properties may be less important than

part cost and model appearance. Concept models are primarily used for visual communication and may be discarded shortly after being used. Verifi cation models may need to simulate fi nal products and need to have functional characteristics that closely resemble fi nal production materials. Materials used for rapid

manufacturing applications may need to be

castable or may need high temperature resistance to perform in application. End use parts will typically need to remain stable over longer time periods.

Each 3D printing technology is limited to specifi c

material types. For in-house 3D printing, materials are typically grouped as non-plastic, plastic, or wax. Your selection of 3D Printer should be based on which material categories provide the best combination of value and application range. Combining multiple technologies can provide additional fl exibility and expand your addressable applications beyond what can be achieved with a single 3D printer. Often, the combination of two less expensive 3D printers may provide more value than one more expensive system and allow for greater application range and print capacity while

staying within a similar investment budget.

Non-plastic materials typically use gypsum

powder with a printed binder and result in dense,

rigid parts that can be infi ltrated to become very

strong. These parts make excellent conceptual

models and provide some limited functional

testing opportunities where fl exural properties

are not required. The bright white base material

combined with exclusive full-color printing

capabilities can produce life-like visual models that do not need additional painting or fi nishing.

Plastic materials range from fl exible to rigid and

some provide higher temperature resistance. Clear plastic materials, biocompatible plastic materials, and castable plastic materials are also available. The performance of plastic parts produced on diff erent technologies varies widely and may not be apparent from published specifi cations. Some 3D printers produce parts that will continue to change properties and dimensions over time or in varying environmental conditions. For example, one commonly reported specifi cation used to indicate heat resistance of a plastic is Heat Distortion Temperature (HDT). While HDT is one indicator, it does not predict material usefulness in applications that exceed the HDT.